Understanding the health of diesel generators is vital for efficiency and longevity. By decoding the smoke signals from the exhaust, we can gain valuable insights into the generator’s performance. This article delves into the practical steps and expert advice needed to master diesel generator maintenance.

Reading the Signs

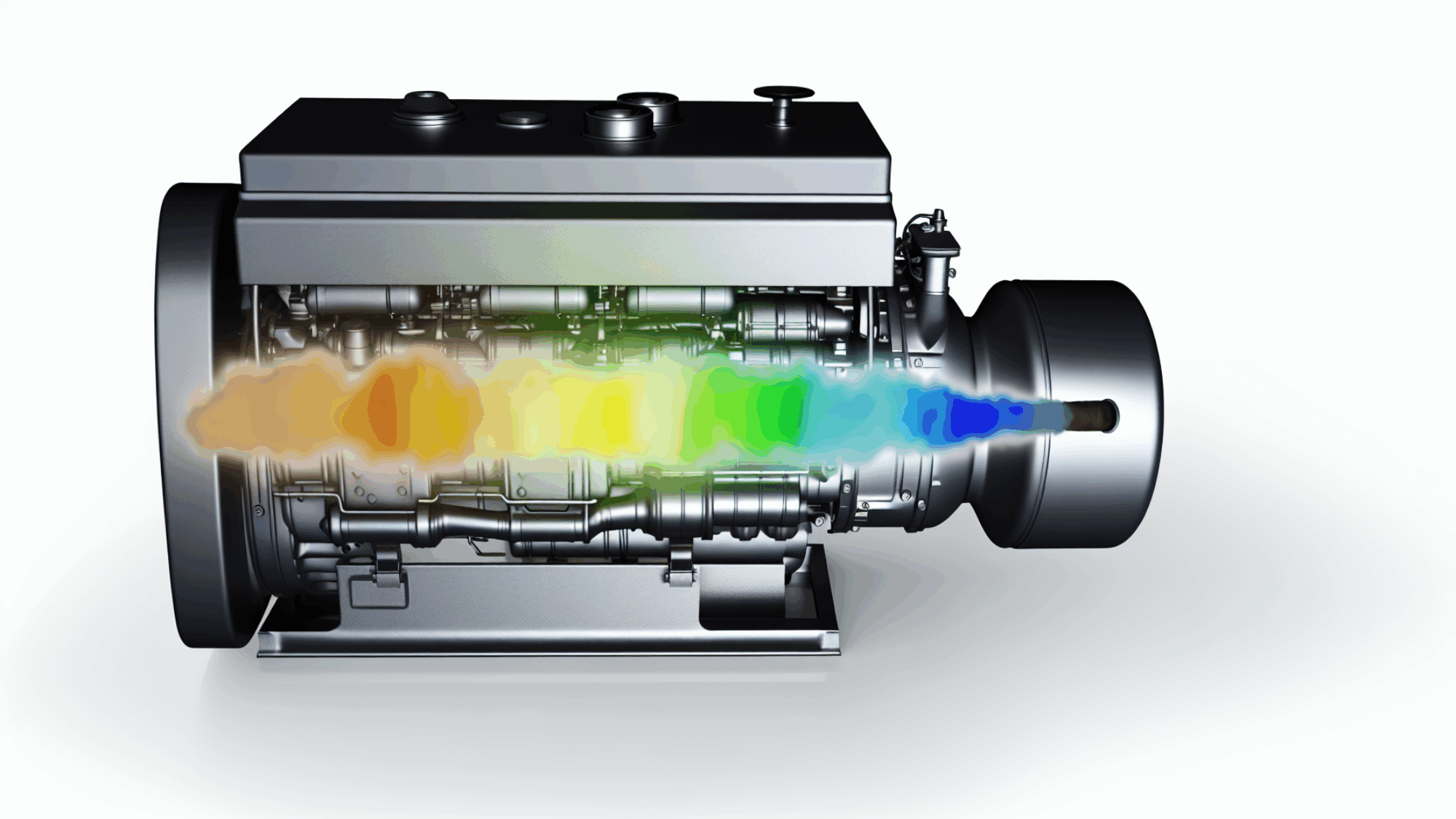

To discern the health of a diesel generator through its exhaust smoke, it’s imperative to understand the implications of the different colors of smoke one might observe. White smoke is generally a sign of unburned fuel. This phenomenon may occur because the engine has not reached its optimal operating temperature, or there could be a malfunction with the fuel injectors, preventing the diesel from igniting properly. Addressing white smoke often involves checking the engine’s heating mechanisms and ensuring the injectors are clean and functioning efficiently.

When the smoke is blue, it usually points to oil being burned within the engine’s combustion chamber. This condition could be the result of oil leaking into the combustion chamber through worn seals or damaged rings and cylinders. Repairing or replacing these components can often resolve the issue of blue smoke.

Black smoke indicates an imbalance in the air-to-fuel ratio, leading to incomplete combustion. The common culprits include a clogged air filter that restricts the flow of air or malfunctioning injectors that deliver too much fuel. To mitigate black smoke, operators should ensure that air filters are clean and injectors are in good working order.

Regular maintenance checks are vital for preventing and addressing these issues. These checks include inspecting and, if necessary, replacing air filters, monitoring engine temperature, and ensuring injectors are clean and functioning as expected. Additionally, the use of diesel particulate filters can help control the emission of smoke, especially in reducing particulate matter, thereby contributing to both environmental protection and the maintenance of generator health.

Understanding these signals and responding promptly to unusual exhaust smoke is key to maintaining optimal generator performance and uptime.

Conclusions

Decoding exhaust smoke is an effective way to monitor the health of diesel generators. By recognizing the implications of different smoke colors, operators can take prompt action to resolve underlying issues. Regular maintenance, along with modern emissions control technologies like diesel particulate filters, can vastly improve generator performance and reduce environmental impact.