Welcome to a transformative exploration of predictive maintenance. In this comprehensive journey, we’ll guide you through the intricacies of using machine learning and log analytics to predict and avoid equipment failures. Understand how to decode generator logs effortlessly and elevate your maintenance strategy in today’s competitive landscape.

Demystifying Log Analytics for Predictive Maintenance

In the realm of predictive maintenance, log analytics merged with machine learning stands at the forefront of innovation. Delving into the intricacies of log files reveals their critical role in performance monitoring. Each log file acts as a diary, meticulously recording events and transactions which, when analyzed, serve as a goldmine for predictive insights. Through advanced parsing techniques, these logs are dissected to unveil patterns and anomalies otherwise invisible to the naked eye.

The process involves employing sophisticated analytical tools that sift through massive datasets to detect irregularities signaling potential failures. Here, the power of statistical models comes into play, enabling the conversion of raw data into meaningful insights. Machine learning algorithms, with their capacity for learning and adaptation, further refine the process. They evolve with each dataset, enhancing their predictive accuracy over time, ensuring that the maintenance strategies they inform are both dynamic and informed.

The translation of these complex analyses into actionable maintenance plans marks a transformative departure from traditional practices. It allows for the optimization of maintenance schedules, ensuring interventions are timely and precisely targeted, thereby minimizing downtime and operational disruptions.

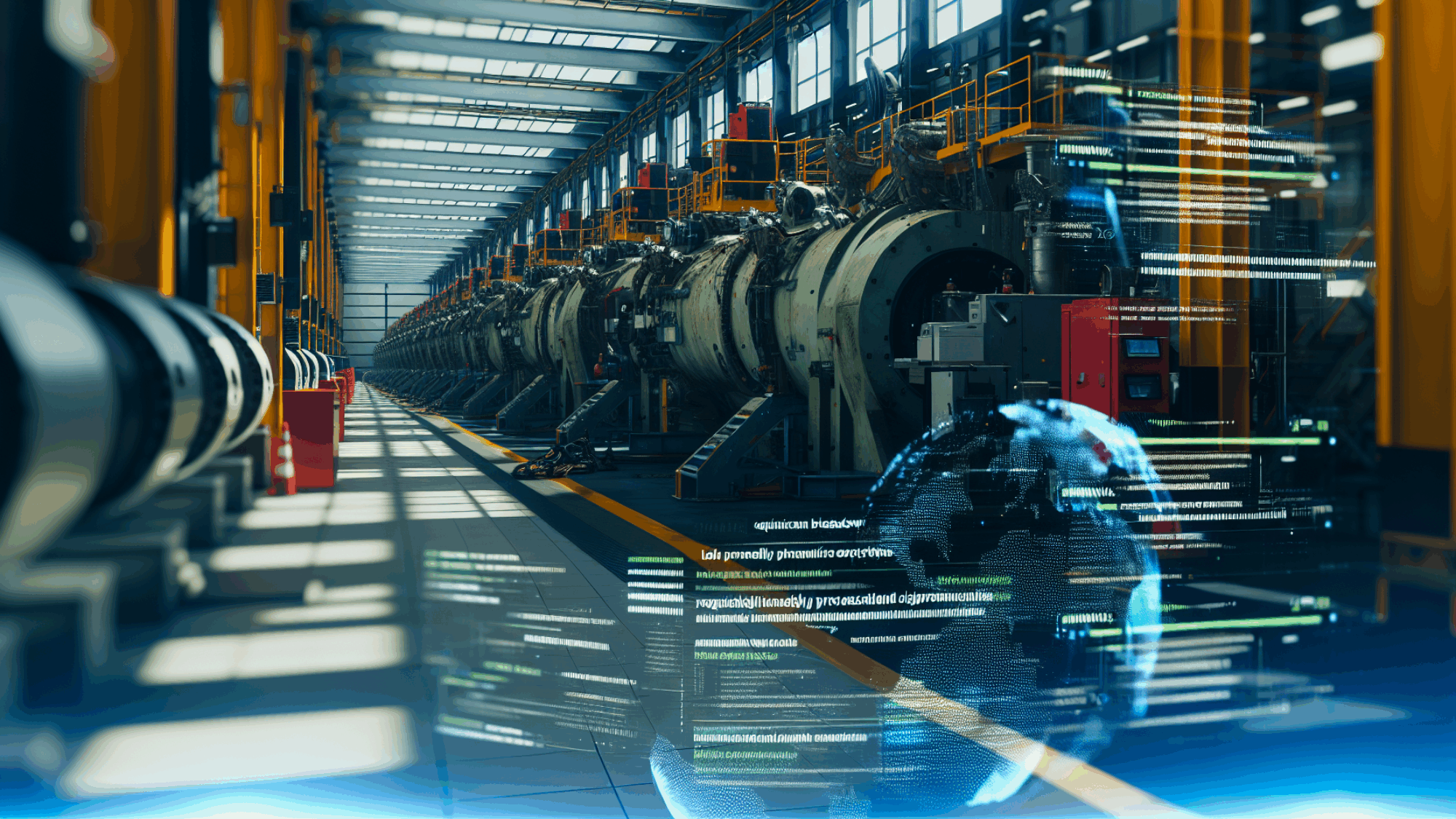

Real-world applications of these technologies illustrate their transformative impact. For instance, in the manufacturing sector, predictive maintenance powered by log analytics and machine learning has dramatically reduced unplanned machine downtimes, directly translating into increased productivity and cost savings. Such success stories underscore the significance of adopting these advanced systems, providing a clear roadmap for others to follow. Experts in the domain advocate for a strategic approach to integration, emphasizing the importance of continuous monitoring and analysis to fully leverage the benefits of these technologies.

In essence, mastering log analytics for predictive maintenance is not just about preventing failures; it’s about redefining maintenance strategies to be more proactive, efficient, and data-driven.

Conclusions

Embracing predictive maintenance empowered by log analysis and machine learning is pivotal for modern industries. We’ve delved into the practical steps to predict equipment conditions, underscoring the significance of proactive measures in sustaining uptime and enhancing operational efficiency.