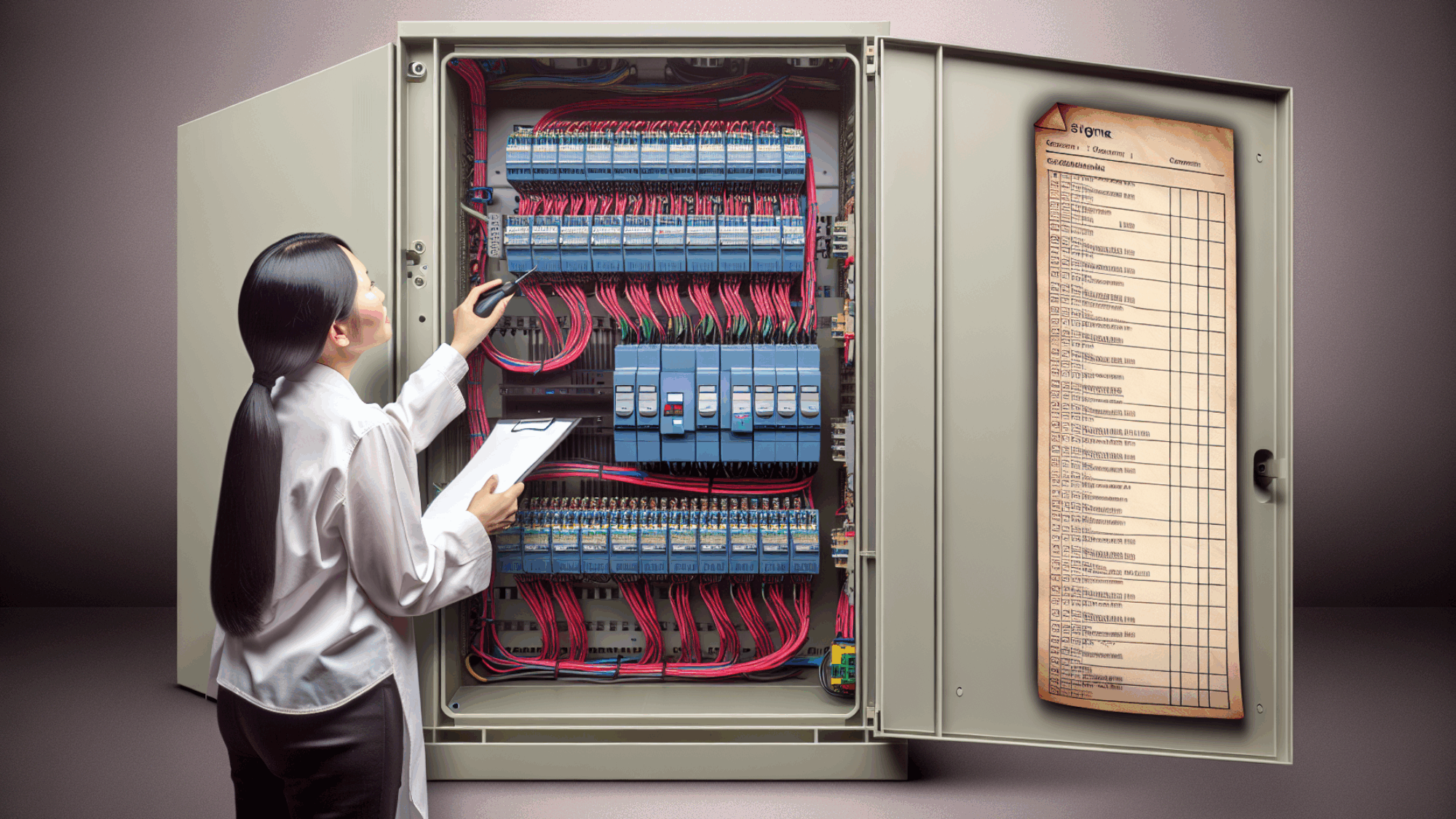

Variable Frequency Drives (VFDs) are at the heart of modern industrial operations, providing vital control over motor speeds and torque. Keeping them in top condition is crucial. In this article, we delve deep into the inspection points within a VFD cabinet that are pivotal to maintaining uninterrupted operations.

Inside a VFD Cabinet

Inside a VFD cabinet, every component is integral to the precise control of industrial motors through the modulation of electrical frequency. Initiating with the examination of AC motor connections, it is crucial to inspect for any signs of erosion or loose connections that can degrade performance or lead to equipment failure. This scrutiny ensures that the power supplied to the motor is stable and efficient.

Progressing to the heart of the VFD, the rectifier bridge converter transforms AC power to DC, and its inspection cannot be overstated. Signs of overheating, such as discoloration of component parts or a burnt smell, indicate potential issues. Equally, the DC link, which stores the converted DC power, must have its integrity verified. Any bulging or leaking capacitors can be catastrophic, and thus, they demand immediate attention.

The assessment of the inverter function, which converts DC back into AC but at the desired frequency, involves inspecting for irregular waveform outputs. Irregular waveforms can significantly affect motor performance, leading to inefficiency and increased wear.

Maintenance of the drive/operator interface extends beyond physical examination to include software diagnostics. Regular firmware updates and checks for error logs can preempt failures. Moreover, in the face of potential issues like overheated components, a malfunctioning cooling system, or worn-out electrical contacts, adopting advanced predictive maintenance techniques using IoT sensors and AI analysis can transform VFD cabinet care from reactive to proactive, immensely reducing downtime and extending equipment lifespan.

Each of these inspection points plays a vital role in maintaining the efficiency and reliability of VFD-operated systems, underscoring the importance of thorough, regular examinations.

Conclusions

Regular inspection and maintenance of your VFD cabinet can prevent costly downtime and extend the lifespan of your equipment. By meticulously following the steps outlined in our guide, you become a steward of your operations, ensuring your VFDs operate at peak efficiency. Remember, a well-maintained VFD cabinet is the cornerstone of a smooth-operating, efficient industrial environment.