As the summer heat intensifies, the threat of unplanned downtime looms over industries. To combat this, smart planning for summer shutdowns is crucial. This article will delve into the strategies that ensure your operations remain uninterrupted, advocating for a proactive approach to maintenance. Dive into insights, real examples, and expert tips on becoming an uptime champion.

Strategizing Preventive Maintenance

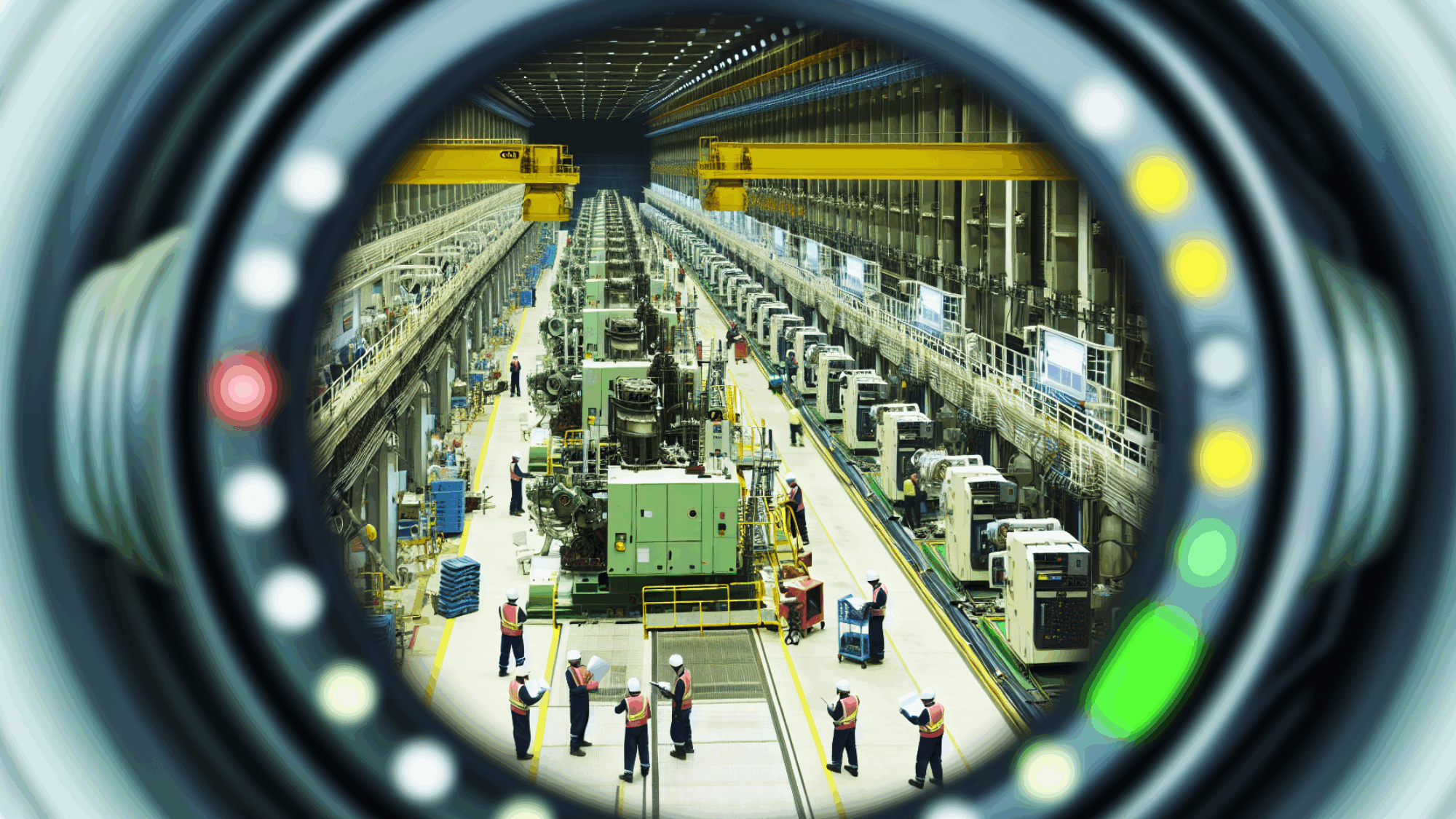

Preventive maintenance is the cornerstone of ensuring uptime excellence, especially during the summer months when high temperatures and staff unavailability can increase the vulnerability of operations. The implementation of a well-structured preventive maintenance program is paramount. This involves conducting equipment checks, servicing, repairs, and replacements at scheduled intervals before failures occur, thereby avoiding unexpected downtime. A pivotal part of this strategy includes the integration of predictive maintenance and planning tools. These technologies enable the proactive identification of potential issues through data analytics and monitoring equipment performance in real-time.

A successful preventive maintenance strategy also necessitates detailed planning. This involves scheduling maintenance activities during periods of low activity or planned downtime to minimize the impact on production. Real examples from industry leaders show that utilizing planned summer shutdowns for comprehensive maintenance activities not only ensures the reliability and efficiency of equipment but also significantly enhances uptime. For instance, a leading manufacturing company successfully implemented a preventive maintenance regime by scheduling significant equipment overhauls during their least busy month in summer, thus ensuring continuous operation throughout the rest of the year.

In conclusion, mastering preventive maintenance requires a strategic approach that combines scheduled servicing with advanced predictive techniques, all while optimizing the timing of maintenance activities to align with the operational calendar. This approach ensures the durability of equipment, reduces the likelihood of unforeseen failures, and guarantees uptime excellence.

Conclusions

Embracing smart planning for summer shutdowns with effective preventive maintenance strategies is pivotal to ensure continuous uptime and avoid panic. By implementing the insights and methodologies discussed, your operations can emerge stronger and more reliable during the challenging summer months.