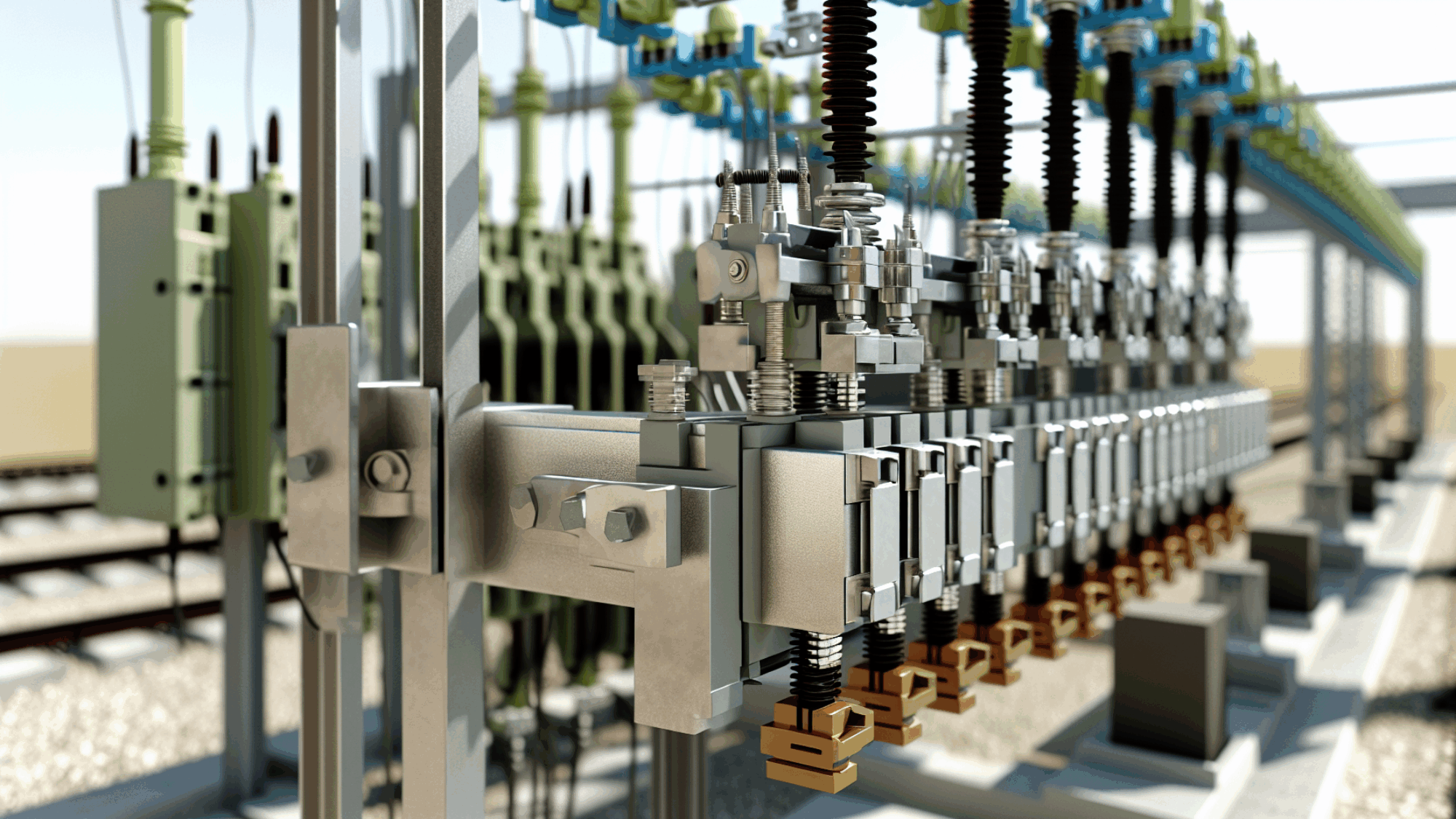

In the realm of electrical power distribution, busbar systems play a crucial role in ensuring the seamless transmission of high currents. However, without diligent maintenance, busbar heating issues can jeopardize operational uptime. Here, we explore comprehensive steps to keep these power arteries in optimal condition.

Mastering Busbar Health

Mastering busbar health begins with an understanding of their crucial role in efficiently distributing electrical power with minimal losses. However, busbars can develop heating issues due to overloading, corrosion, loose connections, and inadequate maintenance, leading to decreased performance or catastrophic failures. Detecting these issues early through initial diagnostics is paramount. Visual inspections for discoloration, infrared thermography to identify hot spots, and ultrasonic testing to detect arcing are vital tools in this phase.

Regular maintenance practices are essential for preventing busbar system failures. Ensuring connections are tightened to the manufacturer’s specifications, cleaning to remove dust and corrosion, and verifying the integrity of insulation can significantly reduce the risk of faults. Furthermore, periodic testing of the busbar’s electrical properties affirms its operational health.

Innovative solutions have emerged to enhance busbar functionality and longevity. Flexible busbars, made from highly conductive materials encapsulated in durable insulation, accommodate movements and expansions in the system, reducing mechanical stresses. Advanced insulation techniques, such as heat-shrinkable or snap-on insulators, provide robust protection against environmental factors and electrical interference, crucial for maintaining busbar integrity. These measures, when effectively implemented, ensure high availability and reliability of the power distribution system, safeguarding operational uptime.

Conclusions

Ensuring the health of busbars is paramount for maintaining operational uptime. Regular diagnostics, preventive maintenance, and the adoption of innovative solutions can mitigate risks of system failure. Stay proactive to safeguard your electrical distribution framework and become an uptime champion.