In the fast-paced world of industry and technology, robotics and automation have become pivotal in advancing maintenance practices. Our article delves into this transformative era, providing insights and examples on how to elevate your maintenance operations through innovation and smart strategies.

The Evolution of Robotics and Automation in Maintenance

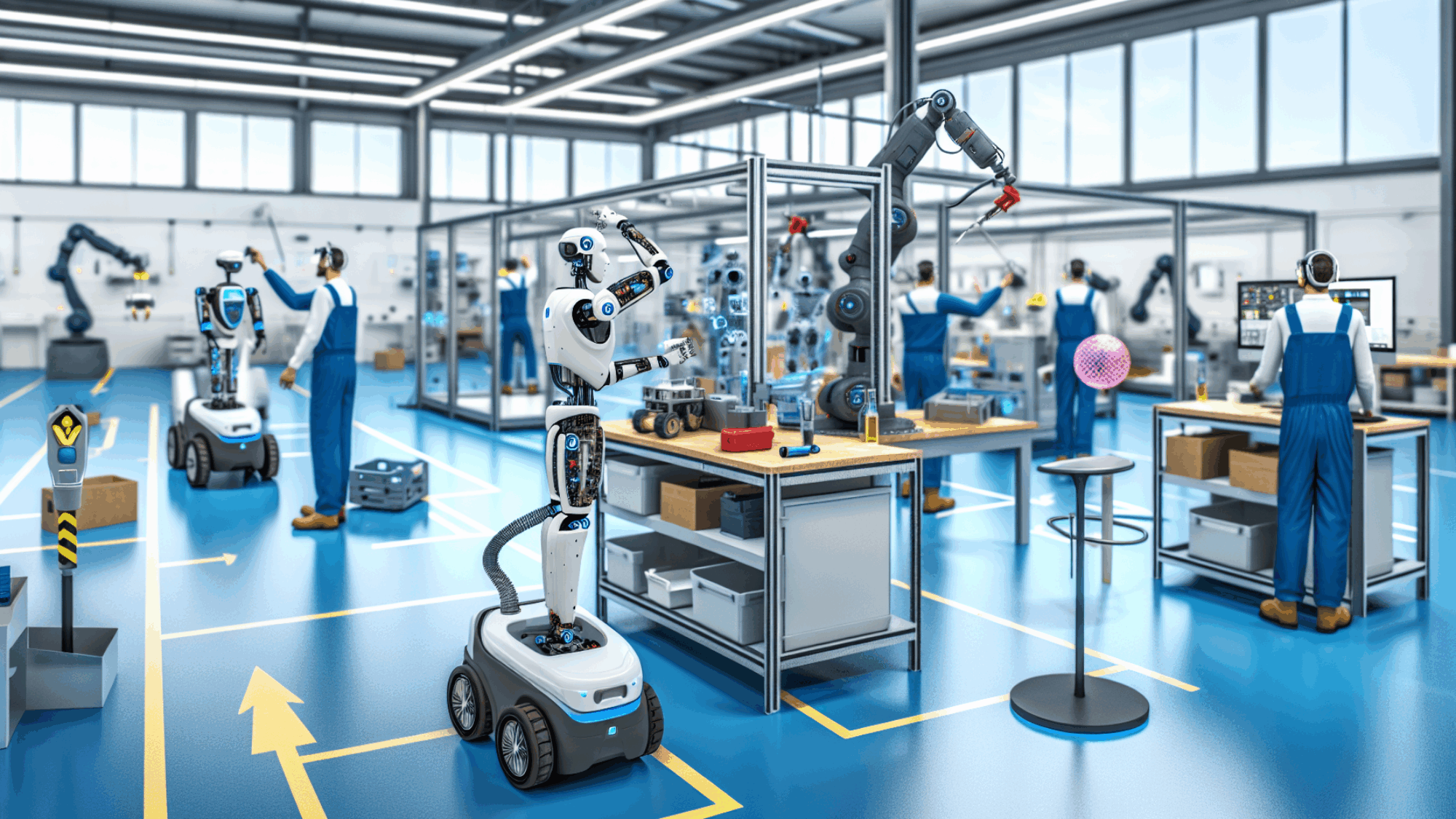

The advent of robotics and automation in maintenance has spurred a transformative shift, with historical roots deeply entrenched in the late 20th century when rudimentary robotic systems began to replace or aid human efforts in hazardous or highly repetitive tasks. Today, the landscape is vastly different, thanks to advancements in technology which have expanded the use of robotics across various sectors including manufacturing, healthcare, and construction. In particular, the integration of collaborative robots (cobots) has revolutionized workplace dynamics, enabling humans and robots to work side by side safely. These cobots are designed with advanced sensors and AI to avoid collisions and adapt to changes in their environment, thus ensuring worker safety.

In healthcare, personal care robots have been developed to assist with tasks ranging from patient lifting to basic companionship, thereby reducing physical strain on human caregivers and improving patient care. Similarly, in the construction industry, robots and exoskeletons are being employed not just for heavy lifting but also for precise tasks like welding or bricklaying, enhancing both productivity and worker safety.

The deployment of autonomous vehicles and UAVs for maintenance tasks, such as inspection of infrastructure or agricultural lands, has reduced the need for human exposure to potentially dangerous or inaccessible areas. However, the incorporation of such advanced robotics into daily operations brings about new challenges in occupational safety. Thus, the establishment of comprehensive hazard controls, including physical barriers, adherence to good work practices, and rigorous maintenance protocols, becomes imperative. Organizations like the Robotic Industries Association (RIA) have been pivotal in developing safety standards, while entities like the National Institute for Occupational Safety and Health (NIOSH) continue to identify research needs to mitigate risks associated with workplace robotics.

Successful case studies, such as the use of UAVs by energy companies to inspect power lines or the deployment of cobots in automotive manufacturing plants, underscore the benefits of robotics and automation in maintenance. These examples not only highlight improved efficiency and safety but also point towards a future where manual labor is significantly reduced, if not eliminated, in high-risk maintenance tasks.

Conclusions

Throughout the evolution of maintenance practices, robotics and automation have emerged as game-changers, drastically enhancing efficiency and safety. By leveraging robotics, businesses not only improve operational performance but also cultivate a safer working environment. As these technologies continue to advance, it is imperative to adopt the latest innovations to remain competitive and ensure success.