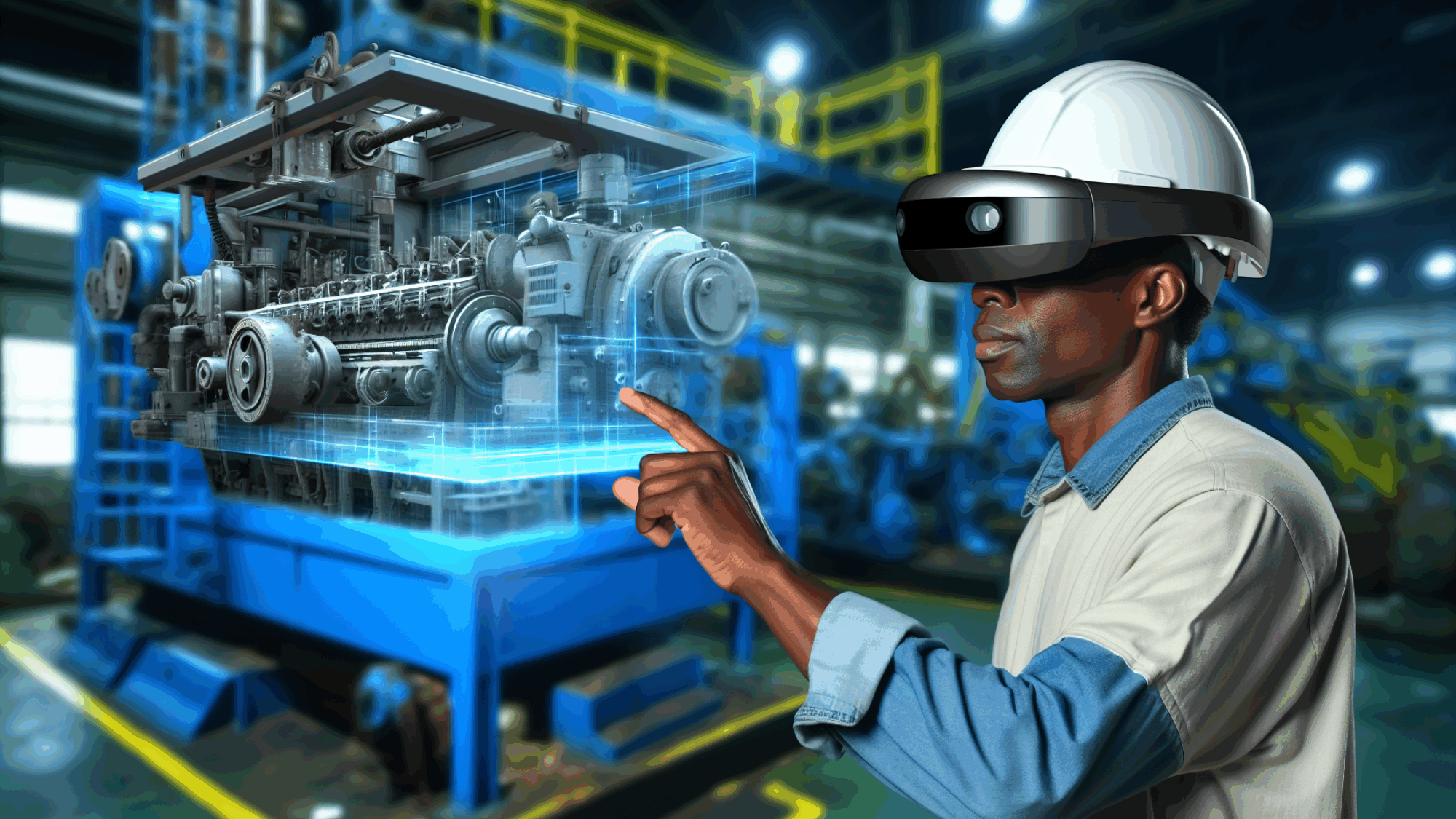

In today’s rapidly evolving industrial landscape, smart helmets equipped with augmented reality (AR) are transforming traditional maintenance protocols. This article delves into how these cutting-edge devices offer real-time insights and guidance, enhancing worker efficiency and safety.

The Impact of Smart Helmets on Modern Maintenance Practices

The advent of smart helmets, such as DAQRI’s augmented reality (AR) wearables, has significantly revolutionized modern maintenance practices in industrial operations. These innovative helmets integrate features like visual instructions, real-time alerts, and 3D mapping, fundamentally changing the approach towards both preventive and corrective maintenance tasks. Through the projection of holographic data into the user’s field of vision, maintenance personnel can receive step-by-step visual guidance during repairs, enhancing precision and reducing the likelihood of errors. This immediate access to crucial information not only streamlines complex tasks but also significantly reduces downtime, a critical factor in maintaining high operational efficiency.

Moreover, the integration of real-time alerts helps in promptly identifying potential issues before they escalate into more significant problems, thereby shifting the focus towards predictive maintenance. This proactive approach aids in foreseeing failures and scheduling maintenance activities accordingly, minimizing unplanned outages. Industries such as manufacturing, energy, and aerospace have been quick to adopt these AR wearables, reporting substantial improvements in training effectiveness and worker safety. The hands-free nature of smart helmets ensures that workers can focus on the task at hand with enhanced situational awareness, thereby improving safety protocols.

The data collected through these smart helmets serve a dual purpose; not only do they assist in immediate maintenance tasks but also contribute to long-term strategic planning. Analyzing this data helps organizations identify recurring issues, optimize maintenance schedules, and even predict future failures, leading to continuous improvement in maintenance operations. Such comprehensive insights pave the way for a more resilient and efficient operational framework, showcasing the irreplaceable role of AR in modern industrial maintenance.

Conclusions

Smart helmets have proven to be game-changers in industrial maintenance, advancing traditional practices into predictive and precisely managed operations. Summarize the article’s insights on the capabilities of AR in maintenance, reflecting on the increased safety, efficiency, and cost-effectiveness that these technologies bring to the forefront of industry standards.