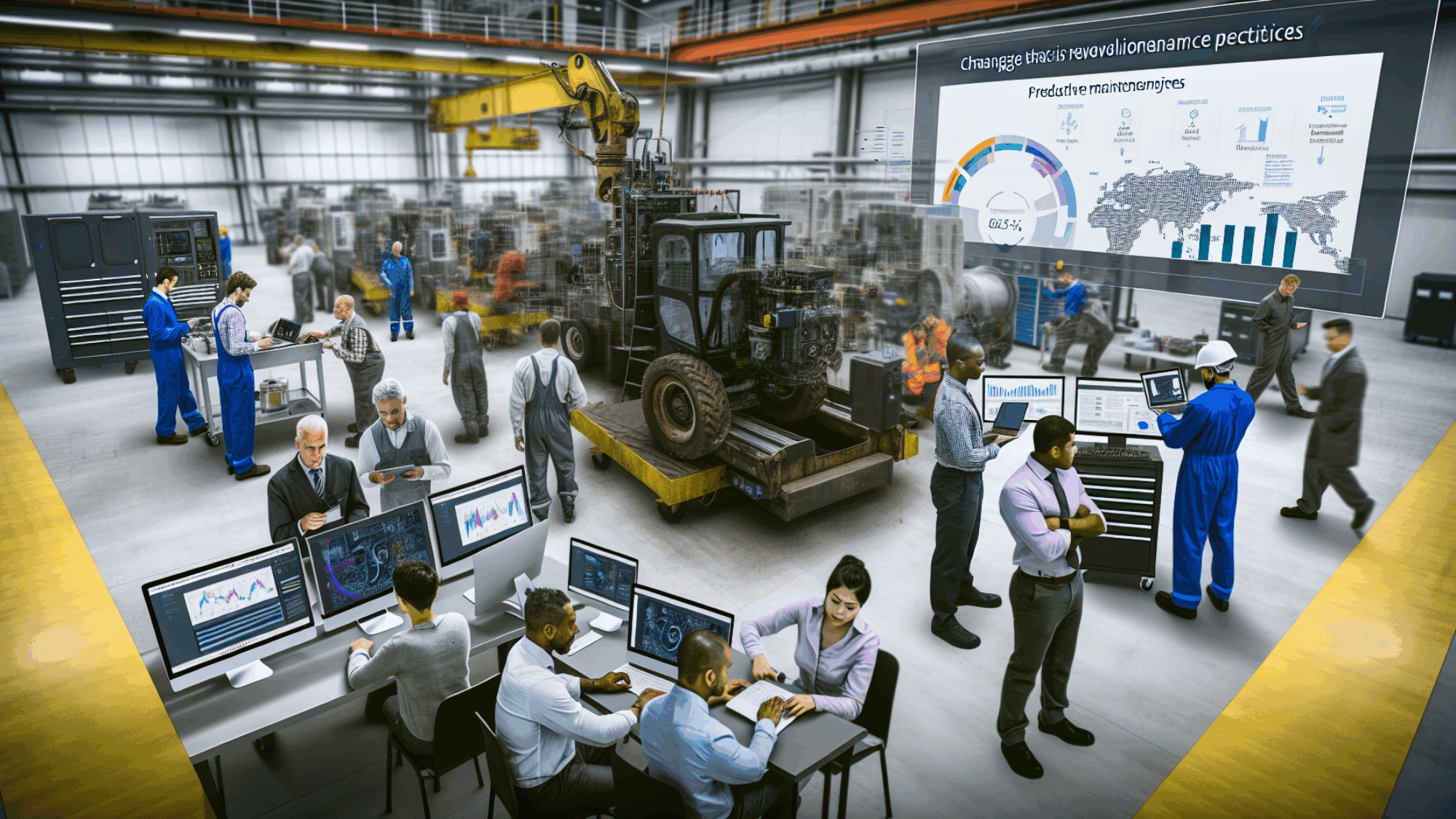

In today’s fast-paced industries, maintenance practices are crucial for reliability and efficiency. This article delves into the transformative impact of weekly wrap, a modern approach that integrates predictive analytics into maintenance strategies to preempt equipment failures and boost operational productivity.

Advanced Maintenance Strategies

The evolution of maintenance strategies has been profound, transitioning from a purely reactive mode to proactive and predictive methodologies. The inception of the weekly wrap approach marks a significant leap forward. This methodology harnesses the power of predictive analytics, integrating it with reliability-centered maintenance principles to craft an analytics-driven, structured system. This strategic fusion enables organizations to not just anticipate potential issues but to also plan effectively, optimizing maintenance schedules in a way that significantly reduces downtime and enhances resource allocation efficiency.

Through the application of predictive analytics, the weekly wrap approach transforms maintenance from a cost center to a value-added operation. It leverages data from various sources, including machine sensors and operational logs, to forecast potential failures before they occur. This predictive capability allows for maintenance activities to be scheduled at the most opportune times, thereby minimizing the impact on production and operations.

Real-world examples underscore the efficacy of these advanced maintenance strategies. Industries such as manufacturing, aviation, and energy have seen remarkable improvements in operational reliability and efficiency. For instance, a manufacturing plant implementing weekly wrap was able to reduce unplanned downtime by 30%, leading to an increase in production output and a reduction in maintenance costs.

However, transitioning to such advanced maintenance strategies presents challenges, including the need for cultural change within organizations, investment in technology and training, and the integration of these strategies into existing operations. Despite these hurdles, the tangible benefits and competitive advantage gained through implementing a weekly wrap approach, underscored by predictive analytics, make it an indispensable strategy for modern maintenance practices. This shift not only enhances the reliability and efficiency of operations but also paves the way for a more sustainable, future-ready approach to maintenance management.

Conclusions

Weekly wrap has redefined maintenance practices, leveraging the foresight provided by predictive analytics to ensure peak equipment performance and reliability. This strategic overhaul not only minimizes downtime but also fosters a culture of proactive maintenance, empowering organizations to make informed decisions that drive operational excellence.