Wearable technology is altering the landscape of maintenance operations. This article delves into how smart devices enhance predictive and preventive maintenance, with a focus on maintaining industrial equipment efficiently. Discover actionable strategies to revolutionize your maintenance routines.

Enhancing Maintenance with Wearable Tech

In the transformative world of maintenance, wearable technology has emerged as a pivotal force, altering traditional processes and ushering in a new era of efficiency and predictability. Devices such as smartwatches and fitness trackers have transcended their initial wellness purposes to play a critical role in the maintenance sector. They are now instrumental in collecting vital data which significantly influences maintenance schedules, enabling a shift from reactive to predictive maintenance models. By monitoring vibrations, temperature, and even audio frequencies, these wearables provide maintenance teams with real-time insights into equipment condition, alerting them to potential issues before they escalate into costly failures.

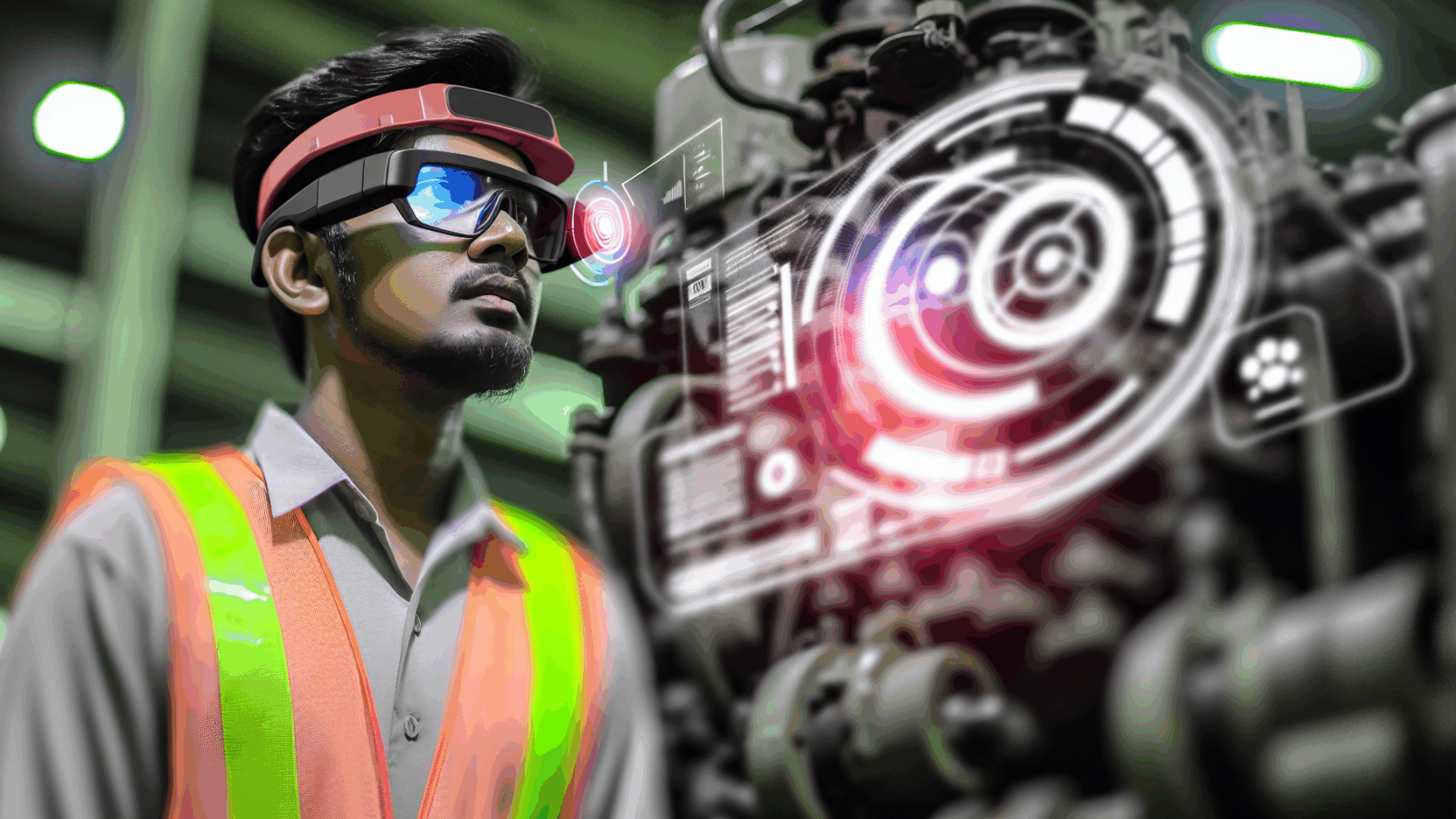

Integrating wearable technology with existing systems requires a thoughtful approach. Experts recommend starting with a clear identification of maintenance goals and challenges, followed by selecting devices that seamlessly mesh with the company’s digital infrastructure. Practical examples include maintenance teams in manufacturing plants using smart glasses to view machine diagnostics in real time, thereby enabling immediate adjustments or repairs without the need for extensive downtime.

However, the adoption of wearable technology in maintenance is not without its challenges. Data privacy emerges as a significant concern, given the sensitive information these devices can collect. Ensuring that data is securely stored and used in compliance with privacy laws is paramount. Additionally, the reliability of these devices in critical applications cannot be overlooked. It necessitates rigorous testing under various conditions to ensure that they deliver accurate and reliable data essential for making informed maintenance decisions.

In conclusion, when carefully integrated into maintenance strategies, wearable technology holds the promise of revolutionizing equipment care, offering a predictive, rather than reactive, approach to maintenance. This shift not only enhances operational efficiency but also significantly reduces the risk of unexpected equipment failures, marking a significant leap forward in maintenance practices.

Conclusions

Wearable technology offers a powerful tool for maintenance teams, providing real-time data that drives efficient and predictive servicing. By embracing these innovations, organizations can ensure equipment reliability, reduce downtime, and optimize resource utilization. With prudent data management and a strategic approach, wearable tech is poised to become a staple in modern maintenance practices.