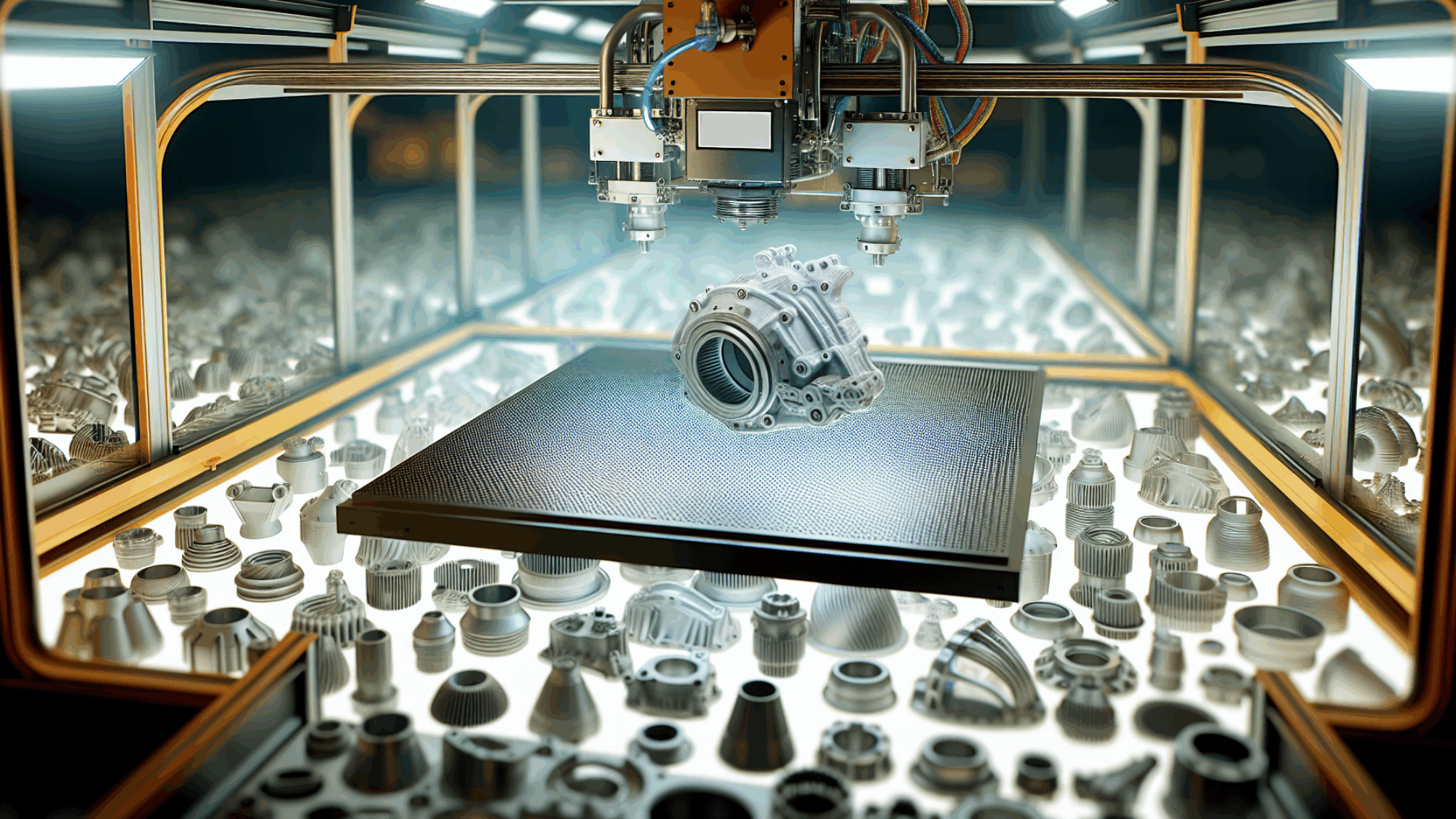

In a rapidly evolving industrial landscape, additive manufacturing, commonly known as 3D printing, is transforming spare parts management. This article delves into how 3D printing is revolutionizing maintenance practices, offering efficiency, cost-effectiveness, and sustainability. Uncover insights and strategies to leverage this innovative technology for your maintenance operations.

Enhancing Maintenance Efficiencies with 3D Printing

Enhancing maintenance efficiencies with 3D printing revolutionizes the traditional approach to spare parts management by drastically reducing lead times and enabling on-demand production. This innovative technology significantly diminishes inventory costs, as companies no longer need to stockpile large quantities of spare parts. Instead, they can print parts as needed, minimizing waste and storage needs. The impact of 3D printing on service parts management is profound, especially in scenarios where the availability of the right spare part is critical to operations. This immediacy ensures high levels of customer satisfaction by minimizing downtime and enhancing service response times.

3D printing allows companies to manage their spare parts more effectively, striking an optimal balance between cost-effectiveness and preparedness for unforeseen breakdowns. For instance, the aviation industry, known for its stringent safety and quality requirements, has already embraced additive manufacturing to supply parts on-demand, reducing airplane grounding times. Similarly, automotive manufacturers utilize 3D printing to produce spare parts for discontinued models, ensuring long-term support for their customers. Through these practical applications, 3D printing demonstrates its indispensable role in modern maintenance strategies, proving that readiness does not have to come at the expense of efficiency or cost.

Conclusions

Additive manufacturing has proven to be a vital asset in modernizing maintenance and spare parts management. By embracing 3D printing, companies can overcome traditional limitations, enhance operational efficiencies, and sustain higher customer satisfaction. This fusion of technology and practicality paves the way for a future where maintenance is synonymous with innovation and strategic foresight.