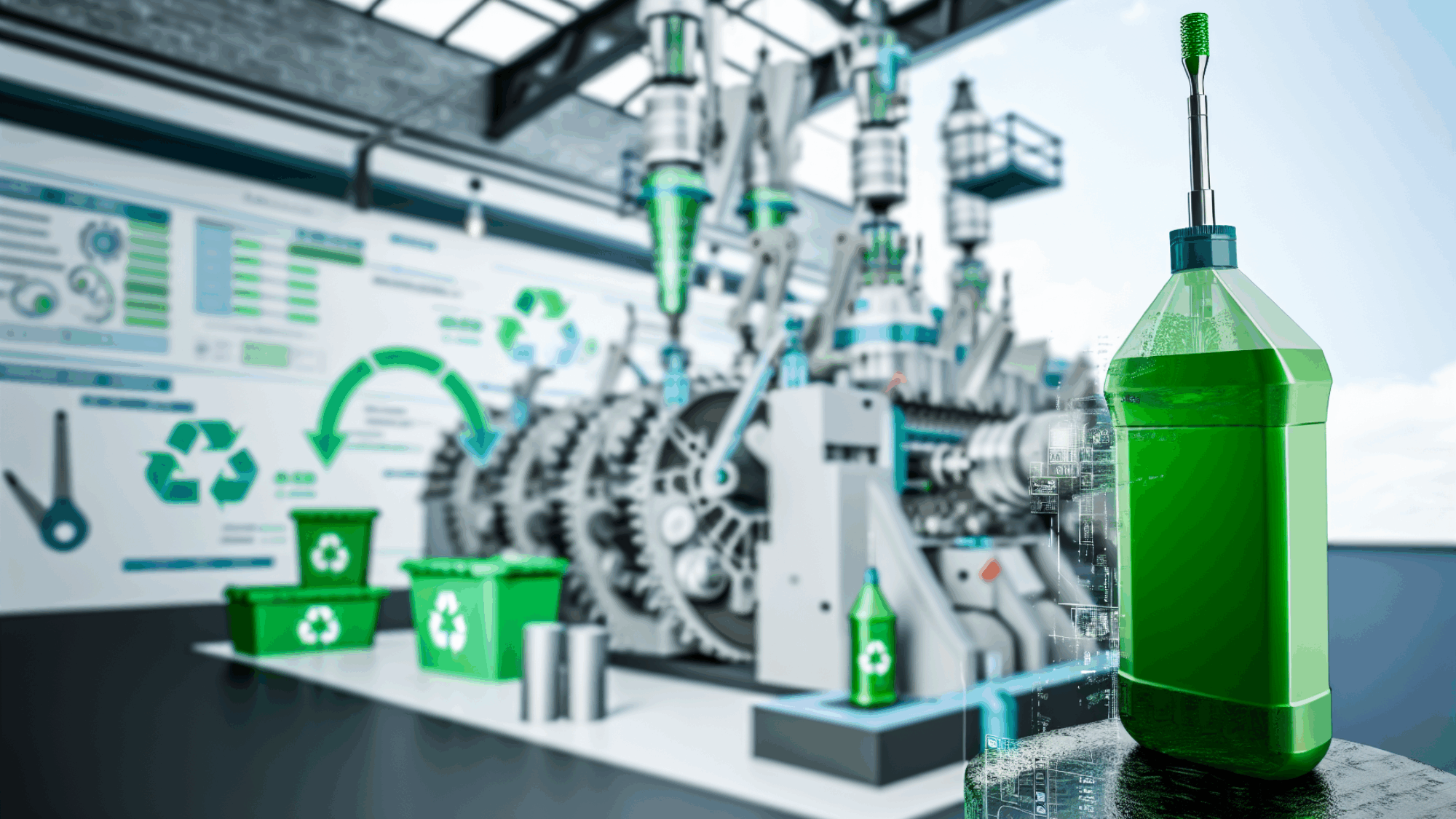

In today’s fast-paced industrial landscape, the shift towards sustainable maintenance practices is crucial. This article delves into how eco-friendly lubricants are transforming maintenance technology with innovative and environmentally-sound approaches, offering practical insights for a greener future.

Eco-friendly Lubricants Paving the Way to Sustainability

Maintenance practices are being revolutionized by the integration of eco-friendly lubricants, heralding a new age of sustainability. These lubricants, characterized by their biodegradability, reduced toxicity, and lower carbon footprint, are setting new standards in environmental stewardship while enhancing the efficiency and cost-effectiveness of maintenance operations.

In the realm of applications, eco-friendly lubricants are not confined to a niche but span across various industries. From the automotive sector, where they ensure smoother and cleaner engine performance, to wind turbines where they reduce the need for frequent maintenance, their versatility is unmatched. The manufacturing industry, too, benefits from these sustainable solutions by minimizing waste and pollution, thus aligning operational practices with environmental regulations and societal expectations.

The transition to eco-friendly lubricants is not merely a compliance measure but a strategic move towards sustainability. Organizations that have adopted these lubricants report not just compliance with stringent environmental standards but also significant cost savings over time due to the extended lifespan of machinery components and reduced maintenance requirements. Moreover, these practices contribute to a company’s sustainability goals by lessening its environmental impact and bolstering its image as a responsible corporate citizen.

Selecting the right eco-friendly lubricant involves considering factors such as the operational environment, machinery used, and specific performance requirements. Implementation requires a strategic approach, including staff training and a thorough analysis of the potential impacts on maintenance routines. The positive outcomes of adopting these lubricants are underscored by examples from leading companies, which illustrate tangible improvements in maintenance efficiency, cost savings, and environmental performance. These insights underscore the pivotal role of eco-friendly lubricants in paving the way toward a more sustainable future in maintenance practices.

Conclusions

The integration of eco-friendly lubricants into maintenance practices is more than a trend; it’s a necessity for a sustainable future. These innovative solutions offer a myriad of benefits, from cost savings to environmental protection, signaling a major leap forward in industrial maintenance. By embracing these greener alternatives, organizations not only contribute to global sustainability efforts but also gain a competitive edge in operational efficiency.