In the rapidly evolving world of industrial maintenance, virtual reality (VR) training has emerged as a transformative force, promising to enhance efficiency, knowledge retention, and safety. This article dives into how VR is reshaping maintenance practices, offering actionable insights and expert recommendations to elevate operational standards.

Revolutionizing Maintenance with Virtual Reality Training

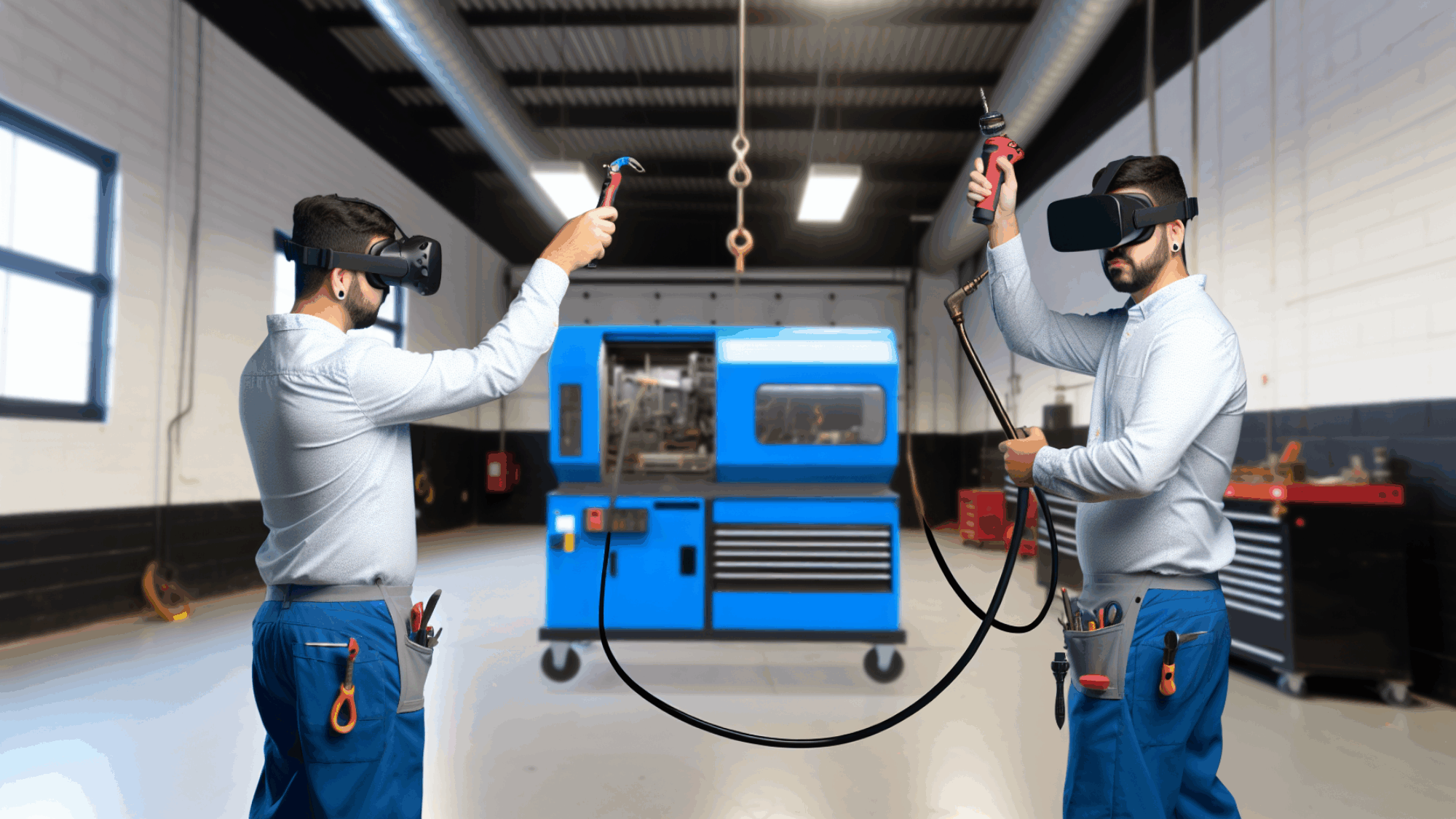

In this era where digital transformation is paramount, Virtual Reality (VR) stands out as a revolutionary tool in the realm of maintenance training. The immersive technology of VR has ushered in an unparalleled method for teaching complex technical skills by simulating real-world scenarios without the associated risks or costs. For example, VR simulations can replicate the intricate process of equipment maintenance, allowing trainees to familiarize themselves with the machinery in a controlled environment. This hands-on experience is invaluable, providing learners with a safe space to make mistakes and learn from them, thus significantly reducing the learning curve when they transition to handling real equipment.

Moreover, VR has proven its worth in conducting emergency response drills. By immersing trainees in virtually replicated crisis situations, VR prepares them for a range of scenarios, enhancing their ability to respond with composure and efficiency in actual emergencies. This aspect of VR training is especially crucial in industries where quick and accurate reactions can mean the difference between safety and disaster.

Another notable advantage of VR in maintenance training is its effectiveness in procedural memorization. Traditional methods of rote learning pale in comparison to the interactive memorization techniques offered by VR, where users can engage in repetitive practice of procedures in a lifelike setting, thereby improving retention and understanding.

Industry experts have pointed out the increased Return on Investment (ROI) from integrating VR into maintenance training programs. Organizations that have adopted VR training report not only a decrease in training costs, owing to reduced need for physical resources, but also a significant improvement in the quality of maintenance performed by their trained personnel.

Despite its numerous advantages, VR training is not without its challenges. Comparing VR to traditional training methods reveals a gap in accessibility and a required initial investment in technology. Moreover, when juxtaposed with Augmented Reality (AR), VR’s immersive nature can be both a strength and a limitation. While AR overlays digital information onto the real world, enhancing the contextual learning experience without detaching the learner from their real environment, VR offers a completely immersive experience that, while highly engaging, requires a complete immersion that may not be suitable for all types of training or for all learners.

However, the prospects for future VR developments within the maintenance sector are promising. Organizations looking to remain at the forefront of the digital revolution in maintenance practices are strategizing the integration of VR technologies into their training programs. By doing so, they are not only enhancing the efficacy and efficiency of their maintenance training but are also paving the way for a future where VR becomes a staple in technical education and training.

Conclusions

VR training has clearly established itself as not just a novel trend but a necessity for modern maintenance practices. The immersive and safe learning environment offered by VR enhances skill acquisition, promotes better retention, and increases engagement. By investing in VR, organizations can ensure they are at the forefront of technology, ready to embrace the full potential of a digitally empowered workforce.