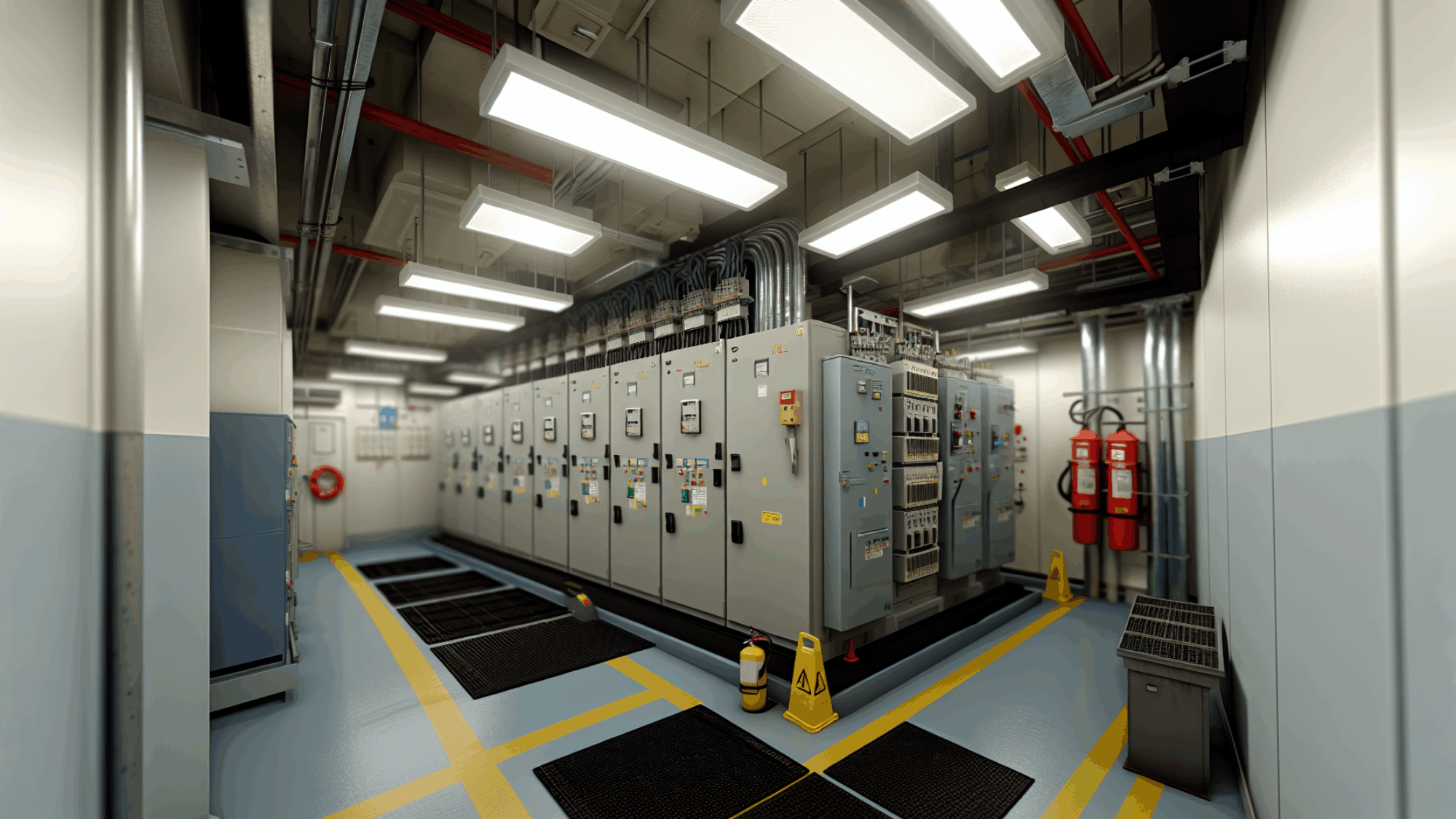

The design of an electrical room encapsulates more than mere efficiency; it incorporates maintenance-readiness as a critical feature. This guide delves into the design practices that not only facilitate efficient operation but also enhance safety during inspections and ensure long-term superior performance of electrical systems.

Principles of Electrical Room Design and Equipment Maintenance

In the realm of electrical room design and equipment maintenance, the fusion of construction features, regulations, and maintenance practices plays a pivotal role in creating an environment that is both efficient and safe. Reinforced floors become essential in bearing the weight of heavy equipment, ensuring the structural integrity of the space. Proper ventilation is not just a matter of comfort but a critical safety requirement, helping to dissipate heat and prevent the accumulation of potentially hazardous gases. The implementation of access control systems is crucial for safety, limiting entry to authorized personnel and reducing the likelihood of accidents.

Adherence to local building and electrical codes cannot be overstressed, as they dictate room layouts, grounding provisions, emergency exits, and the use of fire-resistant materials or suppression systems, especially in the presence of oil-filled equipment. These codes provide a blueprint for constructing electrical rooms that are not only functional but also safe and compliant with legal requirements.

Delving into maintenance, the principles outlined in NFPA 70B underline the significance of both preventive and predictive maintenance techniques. Preventive maintenance ensures that equipment is routinely inspected and serviced, thus preventing failure before it occurs. Predictive maintenance, including condition-based monitoring, goes a step further by using data to predict when maintenance is needed, thereby enhancing resource management. This approach not only extends the life of the equipment but also significantly improves plant safety by preemptively addressing potential issues.

By marrying construction best practices with meticulous maintenance routines, an electrical room can achieve an optimal balance between performance and safety. The ensemble of reinforced structures, precise ventilation, stringent access control, strict adherence to codes, and a robust maintenance strategy exemplifies the essence of a well-organized electrical room that is ready to meet the demands of today’s dynamic operational environments.

Conclusions

Effective electrical room design transcends basic architecture to embrace maintenance-readiness. By integrating reinforced construction, regulated design, access control, and advanced maintenance protocols, we can create spaces that are not only efficient but inherently safer. Predictive maintenance, underpinned by the latest standards like NFPA 70B, takes this a step further by actively extending equipment lifespan and enhancing safety, culminating in a resilient and sustainable electrical environment.