High-quality power is the lifeblood of industrial machinery. Clean and consistent power not only ensures efficiency but directly impacts the lifespan of equipment. This article delves into the intricacies of power quality (PQ), the significance of advanced monitoring systems, the analysis of harmonic distortions, and strategic mitigation methods to uphold machinery integrity.

The Intricacies of Power Quality and Machinery Life

Understanding Power Quality

Power quality, an essential aspect of electrical engineering, is defined by parameters such as voltage, frequency, and waveform purity. Efficient operation of machinery is highly dependent on the compatibility of these parameters with the equipment’s specifications. Deviations in the power supply—such as voltage sags, surges, or frequency fluctuations—can cause machines to malfunction, reduce efficiency, or, more severely, lead to premature failure. These deviations can originate from a variety of sources, including external disturbances from the utility grid or internal disturbances within a facility’s power network. The intricate relationship between power quality and machinery life underscores the necessity for stringent monitoring and management of power supply characteristics to ensure the longevity of equipment.

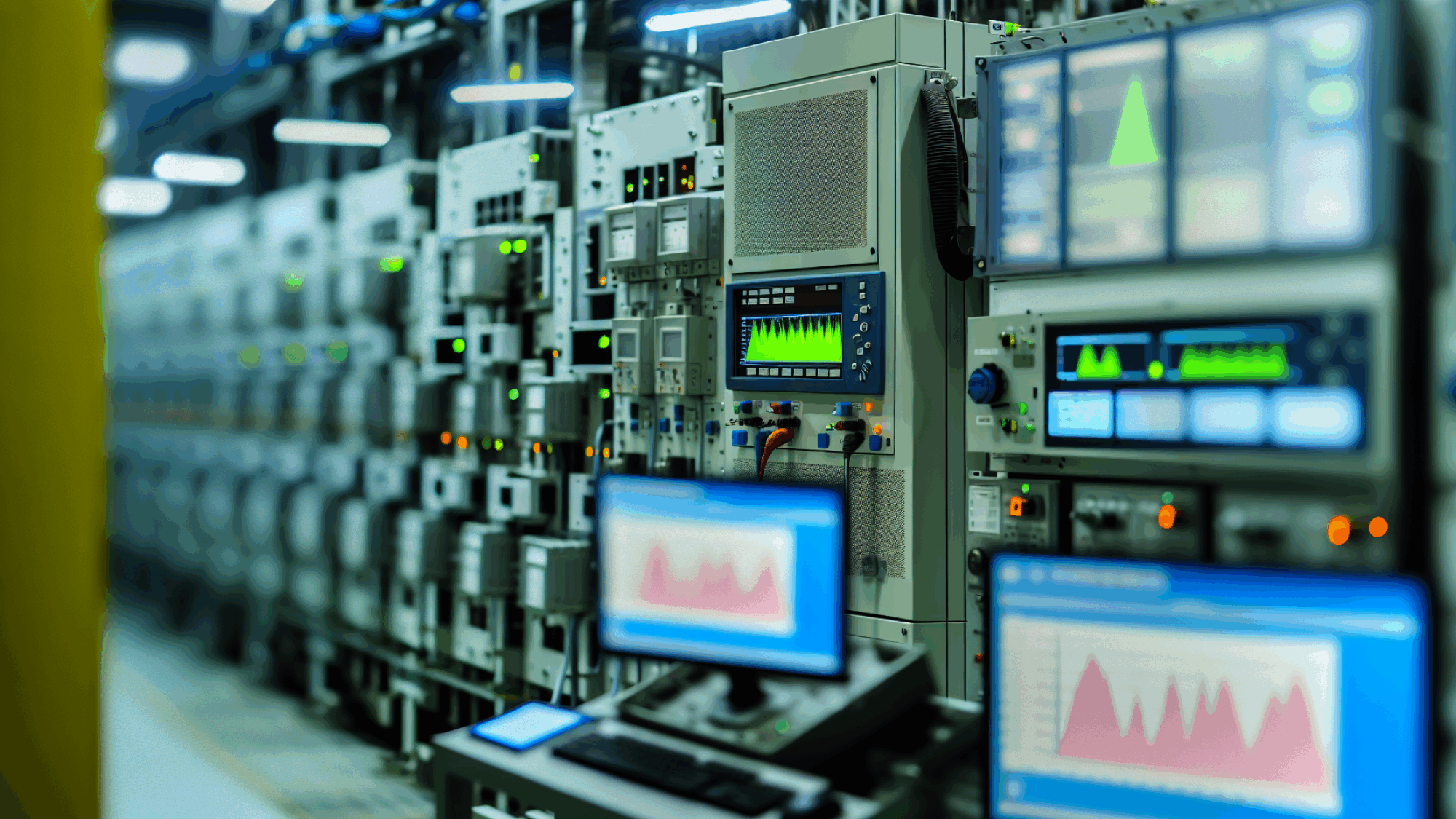

Advanced Power Quality Monitoring Systems

To combat the challenges associated with power quality, advanced PQ monitoring systems, like those developed by SATEC, play a pivotal role. These systems provide real-time insights into the electrical parameters of an installation, detecting anomalies that could potentially harm machinery. Real-time monitoring extends beyond mere issue detection; it facilitates a deeper analysis of power quality trends, enabling proactive measures for maintenance and system adjustment. The technical benefits of such monitoring include prolonged equipment lifespan, reduced incidence of unscheduled downtime, and optimized operational efficiency.

Harmonic Distortion Analysis

Among the myriad power quality issues, harmonic distortion stands out for its insidious effects on electrical systems. Harmonic distortion, a deviation from the ideal sinusoidal waveform of electrical currents and voltages, can lead to overheating, increased wear, and in extreme cases, catastrophic equipment failure. Standards like the IEC 61000-4-7 provide guidelines for measuring and limiting harmonics in electrical installations. Analyzing harmonic sources and their impact on machinery life involves studying case studies and real-world scenarios where harmonic-related failures have occurred, underscoring the critical need for effective management of this power quality issue.

Mitigation Strategies

Addressing power quality issues requires a multifaceted approach. Mitigation strategies such as harmonic filtering, power factor correction, and the implementation of equipment designed to tolerate power anomalies are essential. Harmonic filters—both active and passive—reduce harmonic distortion levels, while power factor correction units improve the efficiency of the electrical system, reducing stress on equipment. Furthermore, designing and selecting machinery with inherent resilience to power quality anomalies can significantly enhance durability. Best practices for industries looking to protect their investments in machinery and equipment include regular power quality assessments, adopting advanced monitoring technologies, and implementing corrective measures tailored to the specific challenges faced. By embracing these strategies, industries can achieve optimal machinery health and longevity, protecting both operational efficiency and financial investments.

Conclusions

This article has highlighted the pivotal role of power quality in safeguarding machinery health and efficiency. Advanced power quality monitoring systems, harmonic distortion analysis, and effective mitigation strategies are crucial for preventing the adverse effects of poor power conditions. By prioritizing power quality, industries can protect investments, minimize downtime, and extend the life of machinery.